A three-step process to Process Improvement success

Departments are encouraged to contact their local HR leader(s) and Organizational Effectiveness (OE) when they have needs that may involve business process improvement. We can provide resources and can refer consultants based upon the need or request.

The University of Iowa first implemented the Lean program in 2006 when we were challenged to do more with less, due to changes in state appropriations and high competition for research dollars. Because the University is committed to excellence, Organizational Effectiveness (OE) started its own Lean practices to help become more efficient, provide higher quality customer service, decrease costs, and improve productivity and results. OE connects campus to tools and HR representatives for process improvement initiatives.

What is Lean?

Lean is about the culture of an organization and a way of thinking. It’s a time-tested proven approach to improving processes within an organization by maximizing value while reducing waste. It also allows an organization to do more with their existing resources. Lean encourages individuals to challenge preconceptions about the way they do what they do. Refer to the Waste Identification site for important discussion of value and the eight forms of waste.

What are the Benefits?

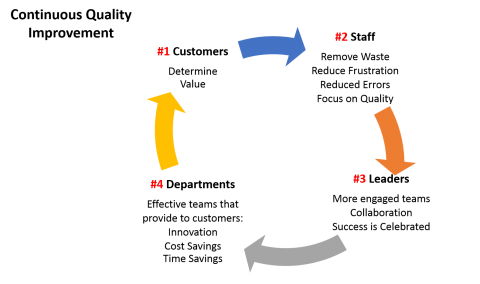

Process improvement benefits all involved parties-the customers, the staff that do the work, the leaders and the departments.

- Customers benefit by reduced waiting time, less errors and higher customer satisfaction ratings.

- Staff benefit by reduced frustration, elimination of wasted time in the process, reduced errors, and better collaboration.

- Leaders benefit by more engaged staff, greater innovation and collaboration and reduced costs.

- Departments benefit by more transparency with engaged teams driving improvements that provide benefits to the customer.

Lean can be expected to:

- Decrease the complexity of processes.

- Provide an opportunity for those who do the work to develop ideas for improvement and efficiency.

- Improve the quality and consistency of results.

- Allocate more staff time to “mission critical” work.

- Improve staff morale.

- Increase process transparency which allows errors or problems to be identified more quickly.

- Gain a shared appreciation for the integral part each person plays in the process being reviewed.

- Create an opportunity for dialogue between all units involved in the process.

How Does Lean Work?

Lean is a very structured review of a business process and the individual steps that make up that process. The review identifies three components related to value or waste, one of which can be attached to every step in the process. The components are defined as:

- Those that add value (defined from a customer perspective),

- Those that don’t add value but are necessary due to laws, regulations or other outside influence, and

- Those that don’t add any value at all and are pure waste. Those steps that are pure waste are targeted for removal.

Removing process steps that add no value is the greatest potential source of improvement. Once waste has been identified and removed, processes are then redesigned to allow the service and/or information to flow through the new process without interruption.

Selecting a Lean Tool

It’s critical for all tools to have the support of management and leaders to ensure that the Lean tool selected will be successful and that the changes made will be sustained in the future. It’s important to remember to choose the right tool by examining which areas of your process are the biggest problem areas at the current time. The University of Iowa offers different tools for your organization to choose from, depending on the current need.